Featured products

Shipcontroller EZVector

Shipcontroller DockerPro

Shipcontroller DockerOne

Dynamic Positioning System

Shipcontroller ShipView R3

Shipcontroller NET

Custom Shipcontroller

Electronic engine control Refit Kits

Shipcontroller technology

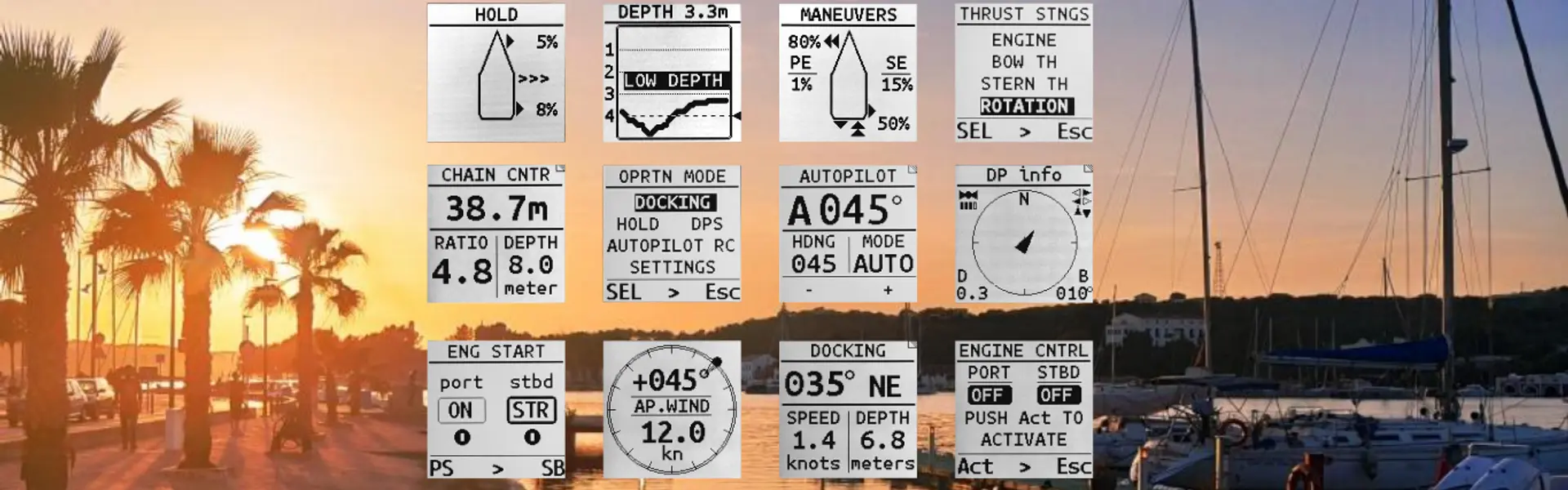

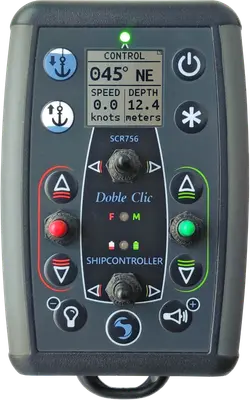

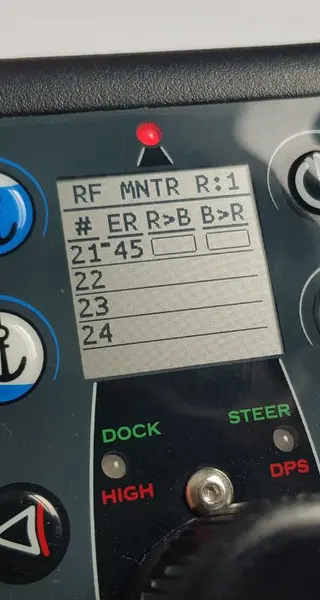

The most advanced Shipcontroller remote controls feature a hybrid technology graphical display with ultra-low power consumption and a high refresh rate. Its features allow for smooth information display without annoying glitches, while also extending battery life.

The display allows you to view navigation information, alarms, graphs, and access the full OnRemoteSetup configuration and settings system.

This feature is available on the EZVector and DockerPro remotes.

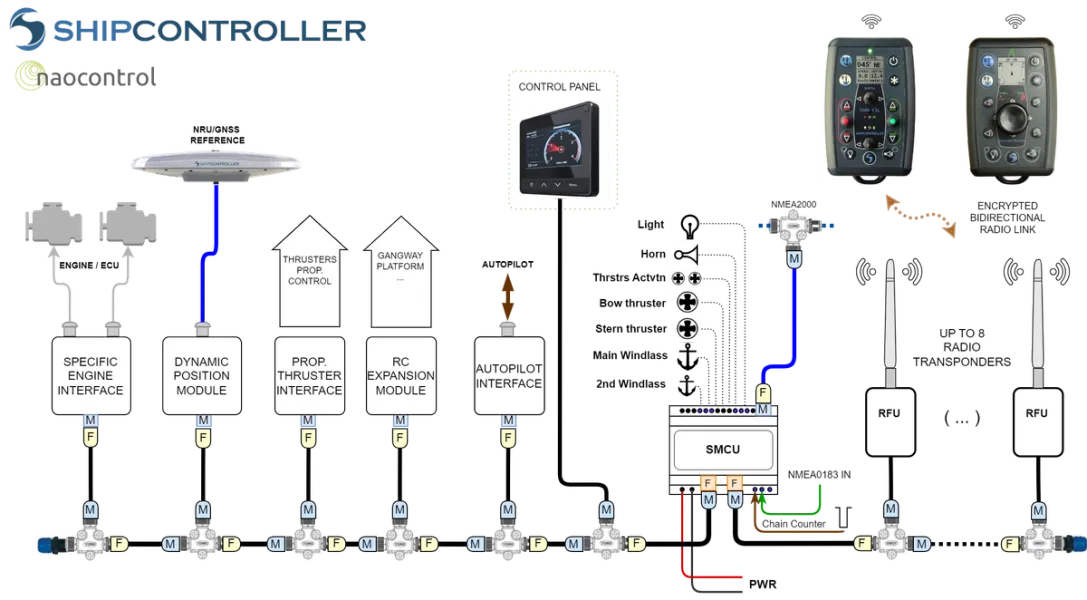

The Shipcontroller base system can be connected to the boat’s data networks, such as NMEA2000®, NMEA0183®, or SeatalkNG®.

Through this connection, navigation data like heading, speed, depth, and wind are collected and transmitted to the remote control via an encrypted radio data channel, allowing them to be displayed on the screen or used for signaling, notifications, or alarms.

This feature is available on the EZVector and DockerPro remotes.

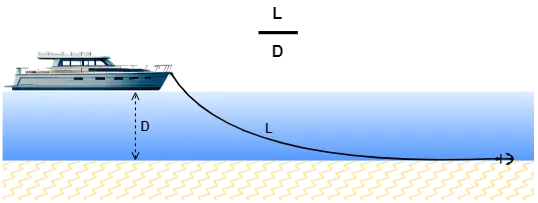

The chain counter function displays the length of chain deployed, the depth of the seabed, and the chain length-to-depth ratio (anchoring scope) on the remote control screen. This ratio is crucial for ensuring proper and safe anchoring.

This feature is available on the EZVector and DockerPro remotes.

The DobleClic feature recognizes a double press of a button or switch, allowing different commands to be assigned to both a single and double press, making it possible to adjust two thrust levels for a thruster or engine, using the remote control's settings menus.

Although it resembles the "click" and "double-click" of a computer mouse, it is slightly different, as the button or lever must be held down for the action to take effect.

For example, the remote control can be configured so that a single press of a bow thruster button applies 60% power, while the "double click" applies 95%.

This feature is available on the EZVector and DockerPro remotes.

The AP Mode of the DockerPro and EZVector remotes allows for control of a compatible autopilot. With the remote, you can switch between Standby and Auto modes, and make course adjustments in increments of ±1º or ±10º.

This feature is available on the EZVector and DockerPro remotes, and requires a specific interface adapter.

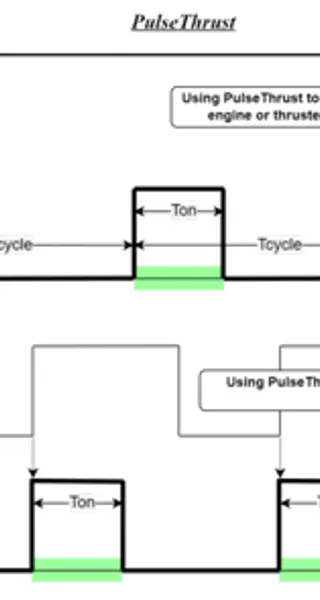

The PulseThrust function reduces the average thrust of an engine or thruster by applying long-cycle pulse width modulation (long-cycle PWM). It also allows for precise impulse durations. This technique is useful in the following scenarios:

- Engines, when idling, have very high thrust, making it difficult to control the boat's speed during low-speed maneuvers.

- Precise duration engine impulses are desired.

- Reduced average thrust is needed for on/off type thrusters; for example, to achieve parallel movement with SwayEase or to use Hold mode with on/off control thrusters.

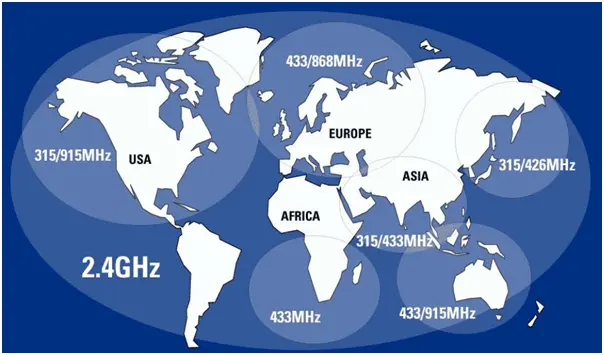

Shipcontroller uses a bidirectional radio communication system based on the standardized IEEE 802.15.4 protocol in the 2.4GHz band, offering numerous advantages:

- The bidirectional radio allows for continuous dialogue between the remote controls and the boat's transceivers. The radio link is permanently monitored, and the remote will immediately alert you in case of a radio link loss, loss of engine control, or other events or incidents.

- The 2.4GHz band and the 802.15.4 protocol are worldwide approved, unlike the 833MHz and 915MHz systems, which have significant regional restrictions. This means you can use your Shipcontroller system globally without legal limitations.

- Although it uses the same radio band as WiFi, the radio channels are different (there are 16) to avoid potential interference.

- It provides robust and reliable communication thanks to the DSSS (Direct Sequence Spread Spectrum) technique:

- It spreads the signal over a wider frequency band than necessary, distributing the energy across a broader spectrum, making it more resistant to narrowband interference.

- The signal is modulated using pseudo-random sequence codes. Only the receiver that knows this sequence can demodulate and recover the signal, reducing the possibility of interference or signal corruption.

- It offers an adequate data transmission speed to support a virtually unlimited number of control channels and the telemetry of navigation data.

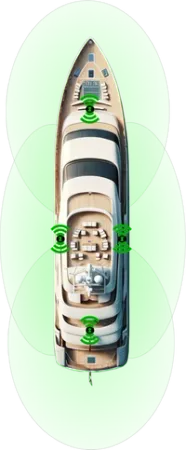

- It supports point-to-point and multipoint configurations, allowing the implementation of the Shipcontroller NET system with multiple radio nodes and multiple remote controls.

- It supports 128-bit AES encryption for secure communications.

Each Shipcontroller system has a unique set of keys and identifiers, making it very difficult for the radio system to be intercepted: there are 10³⁸ possible keys.

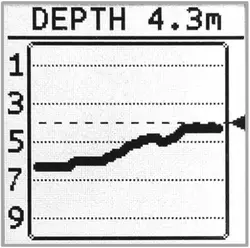

The depth graph and depth alarm functions are very useful during boat maneuvers, as they allow you to monitor the depth and avoid accidental grounding, especially when using the remote control away from the helm station, where you cannot see the boat’s instruments.

The Shipcontroller system collects depth data from the boat’s data networks and sends it to the remote control, which generates a depth trend graph and displays it on the graphical screen.

Additionally, the user can set the depth alarm threshold, so that the remote will alert with a message and vibration if the depth becomes too shallow.

This feature is available on the EZVector and DockerPro remotes.

WindlassGuardian protects the anchor windlass and the bow of the boat from the shocks and strains that can occur when raising the anchor or if the end of the anchor line is reached while deploying it.

WindlassGuardian allows setting chain counter limits for both lowering and raising the anchor, so that:

- If you are raising the anchor and the limit is reached (for example, 1.5 m): The windlass will stop, and the remote control will display a message on the screen and notify you with a vibration. To continue raising the anchor, you must release the windlass button and press it again.

- If you are lowering the anchor and the descent limit is reached: The windlass will stop. The remote control will display a warning message and notify you with a vibration. You will not be able to continue lowering the anchor from the remote control.

Compatibility

The essential requirement for a remote control of motorboats is the ability to manage the vessel’s propulsion systems (engines and thrusters), as well as secondary functions like the windlass or the boat's horn. Additionally, for its more advanced features, Shipcontroller needs to connect to other onboard systems, such as navigation data networks.

To achieve this, Shipcontroller includes the following in its compatibility list:

- Most major electronic engine control systems.

- Most major bow and stern thruster systems, including the latest continuous control thrusters.

- Most anchor windlasses and chain counter technologies.

- The main marine communication buses: NMEA2000®, SeatalkNG®, NMEA0183® (Shipcontroller is a member of NMEA.ORG).

Shipcontroller is constantly working to expand its compatibility list, incorporating the latest advancements such as electric and hybrid propulsion systems, and proportional thrusters. Additionally, it develops new interfaces for outdated control systems, helping to extend their operational life.

Shipcontroller Architecture